Functions

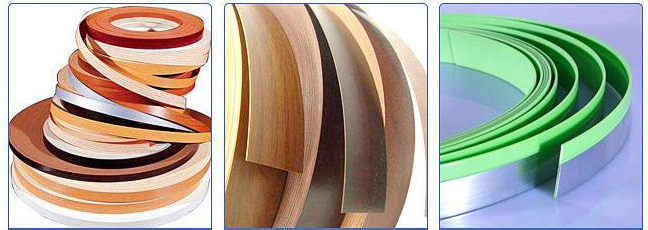

The automatic edge bander machine is applying to the linear sealing of PVC, wood strip and veneer etc.

● The edge bander is heavy, strong and durable service.

● High efficiency and accuracy.

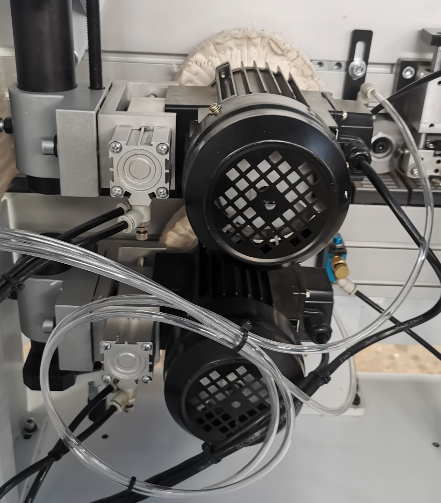

● Using imported engines and electric components.

● The pressing system of automatic edge banding machine is controlled by electrical switch. It works easily.

Technical Data

|

Model |

HZ450DJK |

|

Edgeband thickness |

0.4-3mm |

|

Edgeband width |

10-60mm |

|

Panel min. width |

80mm |

|

Feeding speed |

12-20m/min |

|

Air pressure |

0.8Mpa |

|

Total power |

17.4kw |

|

Overall dimension |

6800X1100X1600mm |

|

Weight |

2800kg |

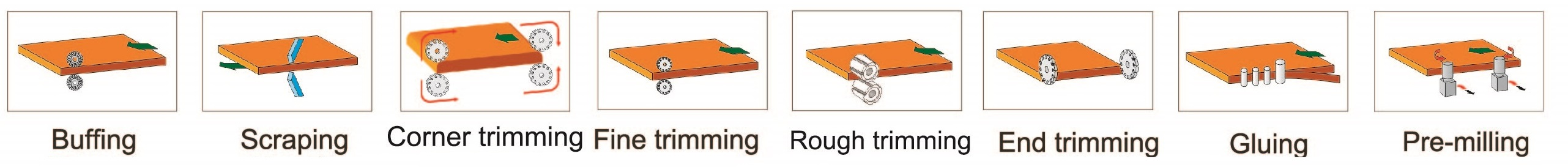

Function

1. Touch screen: Touch screen is Delta brand and it makes your work easier.

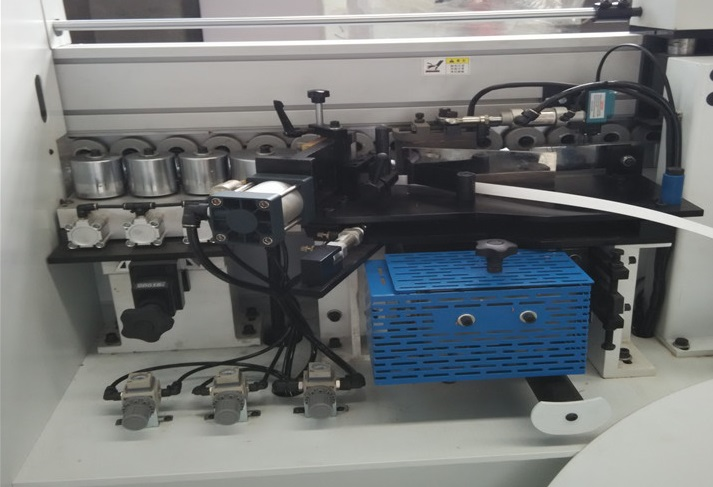

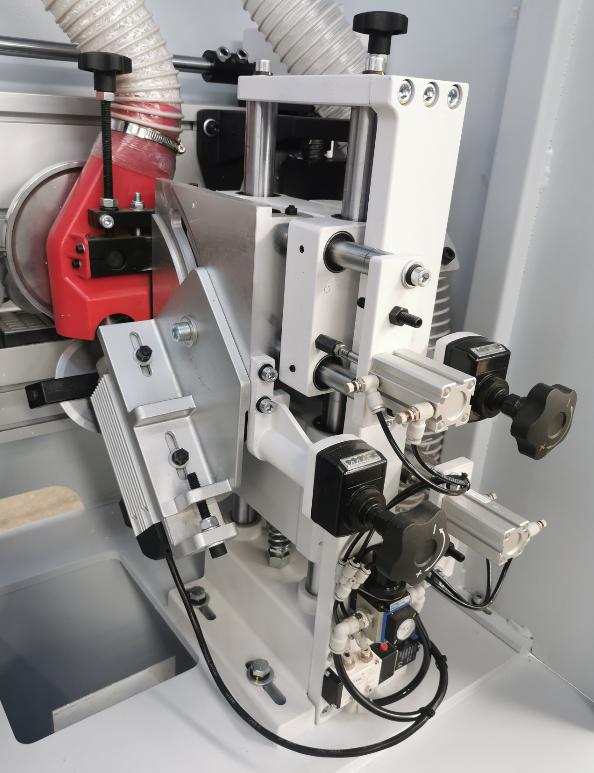

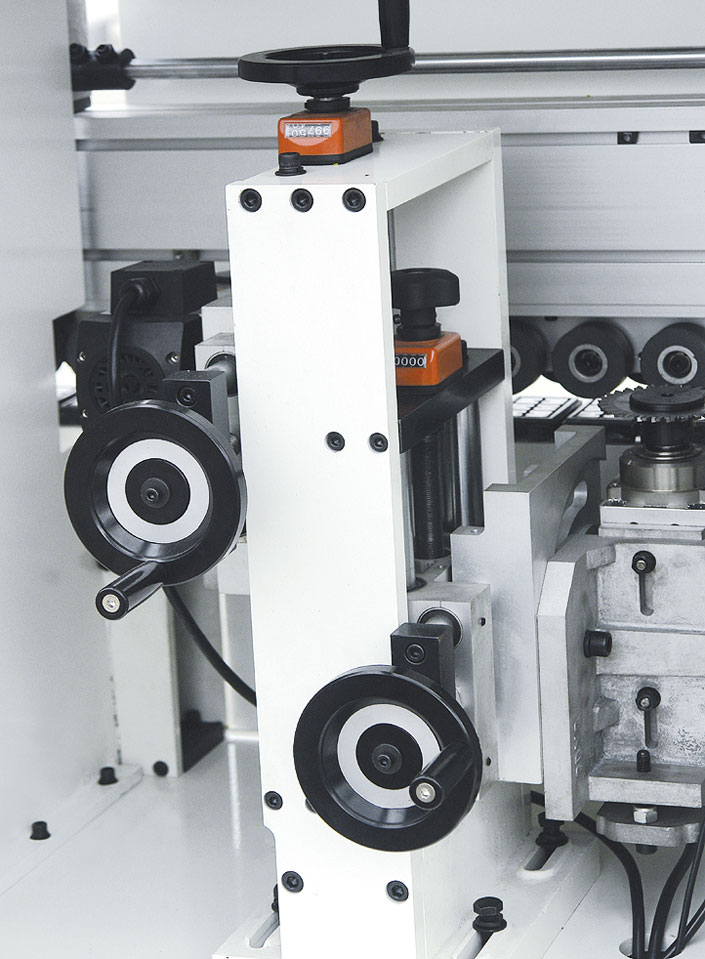

2. Pre-milling group: It has two trim-blades to make the edge of rough panels flatter so that panels edge be coated glue evenly.

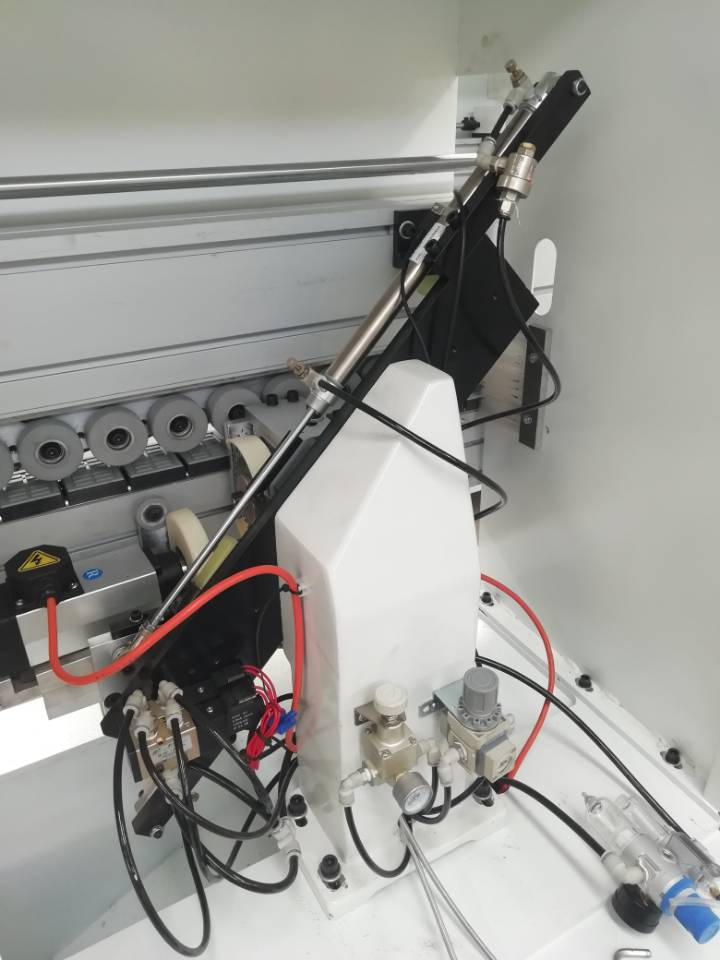

3. Glue tank: It can coat adhesive on edge band and boards uniformly because it is designed a special structure . Edge band and boards can bond together firmly.

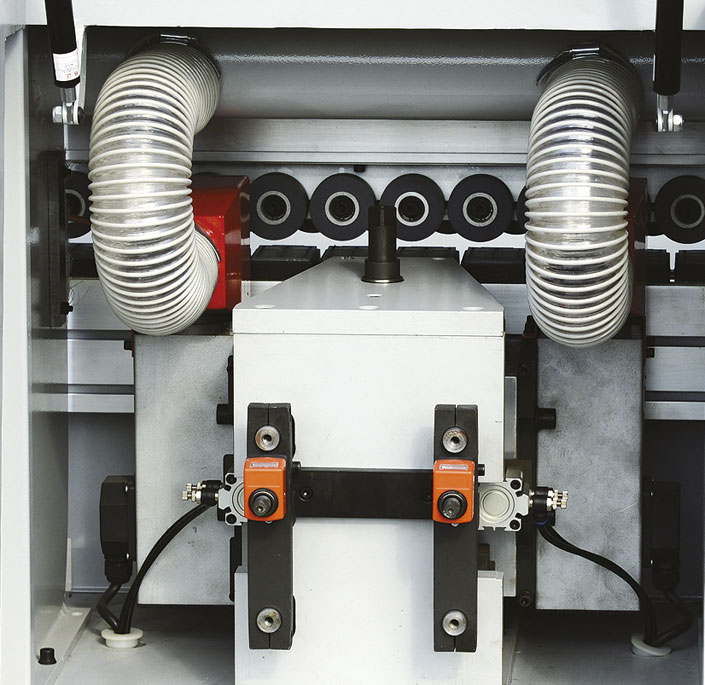

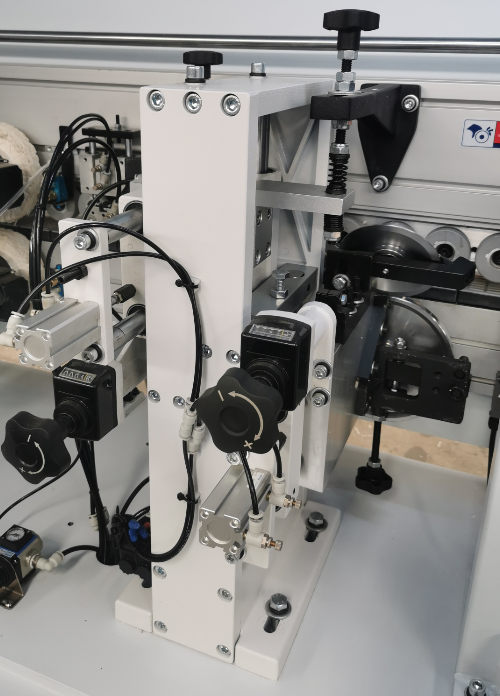

4. End trimming group: It works by a precise guide track movement. The structure of automatic tracking and high -frequency motors can make the surface of edge band smooth.

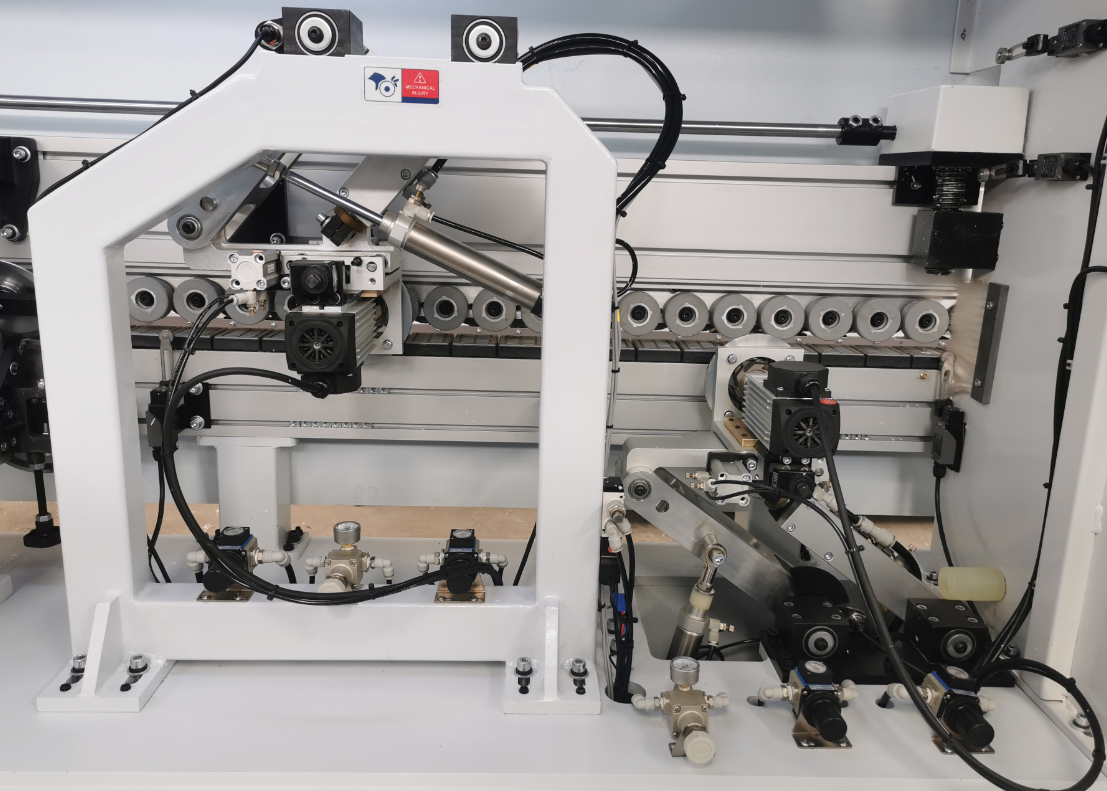

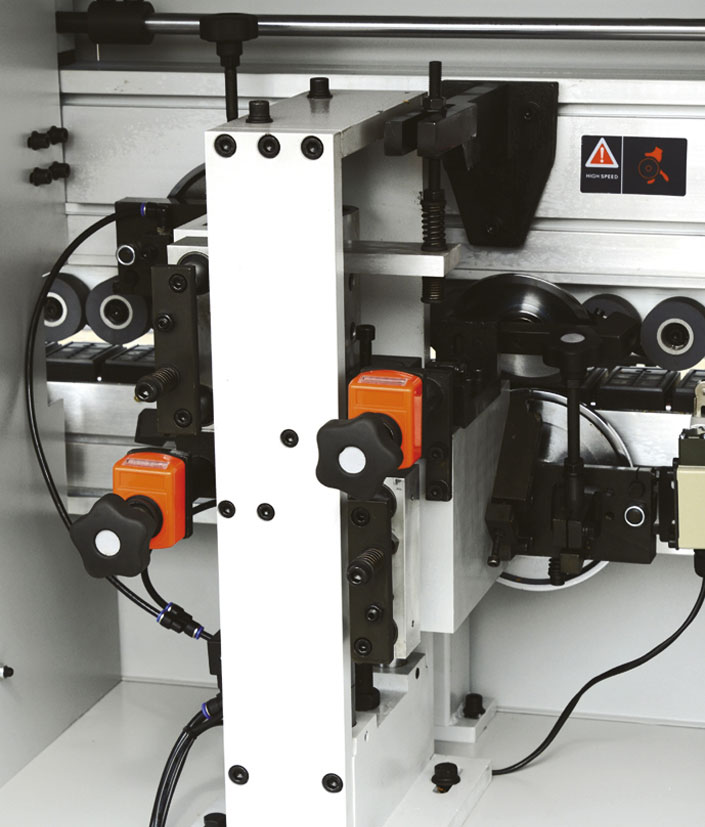

5. Rough trimming group: It can trim the exceeding edge on the panel roughly. It has double individual high- frequency motors.

6. Fine trimming group: It has two individual high- frequency motors and automatic tracking devices. It can make R2 on surface of edge band.

7. Corner trimming group: It makes corner of panels smooth and beautiful.

8. Scraping Group: It makes the surface perfect finishing after the borads be scraped

9. Hogging: Make a straight groove on the bottom or top of boards .

10. Buffing group: The edge of board is very smooth after the boards are polished. It has two polishing wheels and two motors.

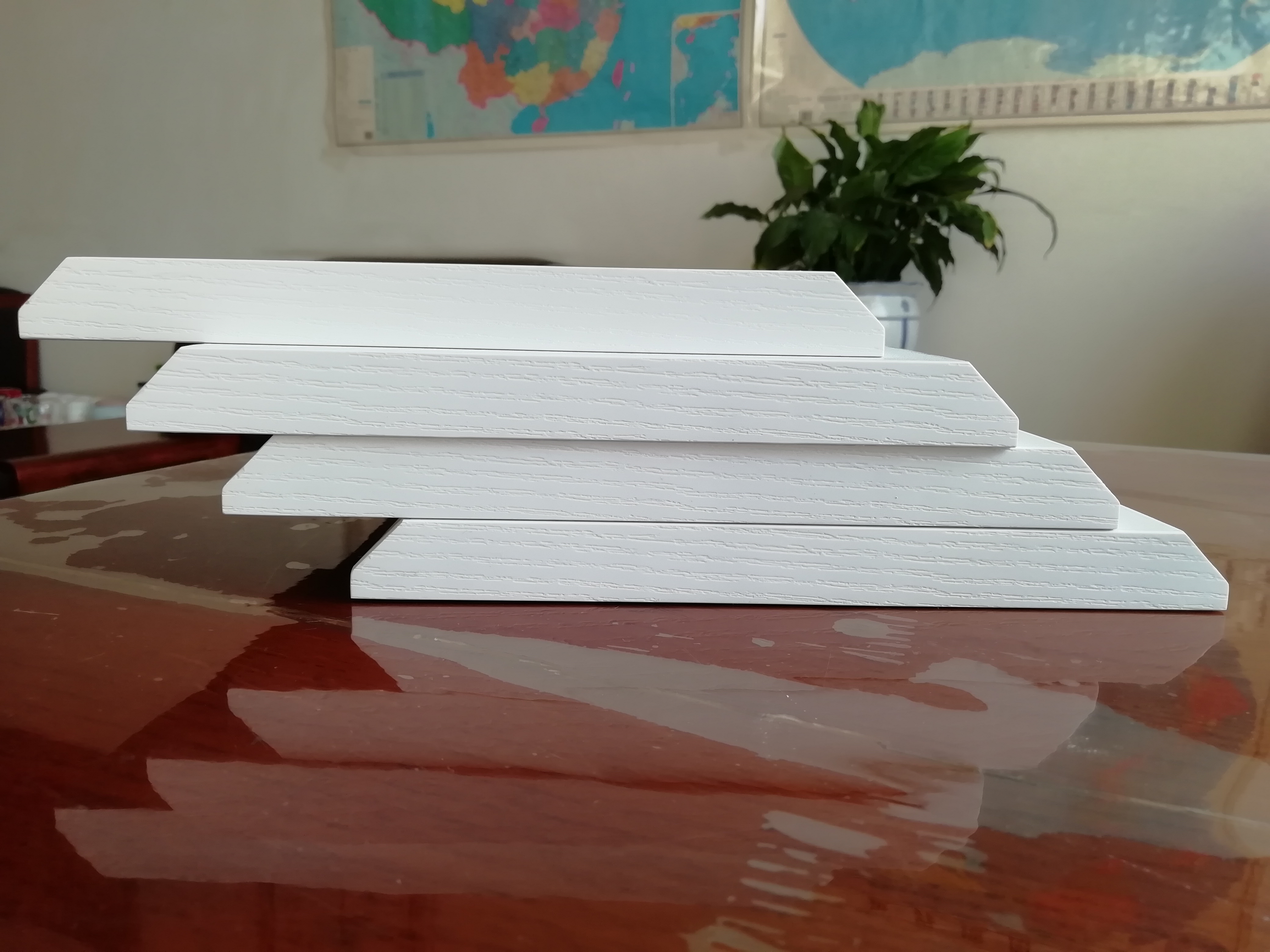

Material Photo

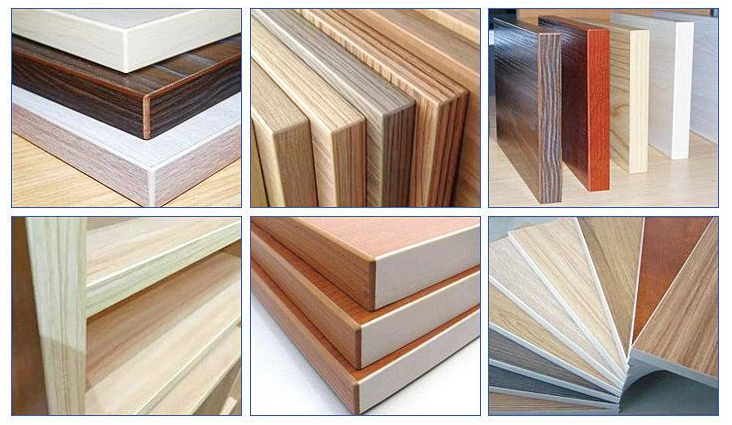

Finish Prouct Photo

Factory Photo