Fixed Competitive Price Industrial Edge Banding Machine - Automatic edge banding machine with pre-milling and hogging HZ450DJK – Golden Detail:

Functions

The automatic edge bander machine is applying to the linear sealing of PVC, wood strip and veneer etc.

● The edge bander is heavy, strong and durable service.

● High efficiency and accuracy.

● Using imported engines and electric components.

● The pressing system of automatic edge banding machine is controlled by electrical switch. It works easily.

Technical Data

|

Model |

HZ450DJK |

|

Edgeband thickness |

0.4-3mm |

|

Edgeband width |

10-60mm |

|

Panel min. width |

80mm |

|

Feeding speed |

12-20m/min |

|

Air pressure |

0.8Mpa |

|

Total power |

17.4kw |

|

Overall dimension |

6800X1100X1600mm |

|

Weight |

2800kg |

Function

1. Touch screen: Touch screen is Delta brand and it makes your work easier.

2. Pre-milling group: It has two trim-blades to make the edge of rough panels flatter so that panels edge be coated glue evenly.

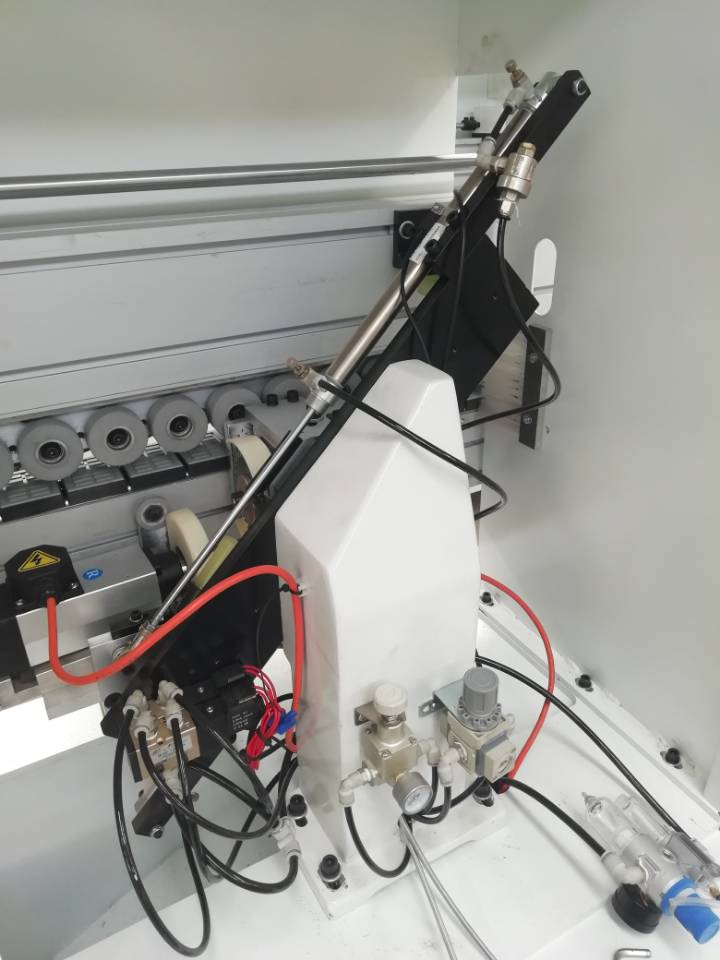

3. Glue tank: It can coat adhesive on edge band and boards uniformly because it is designed a special structure . Edge band and boards can bond together firmly.

4. End trimming group: It works by a precise guide track movement. The structure of automatic tracking and high -frequency motors can make the surface of edge band smooth.

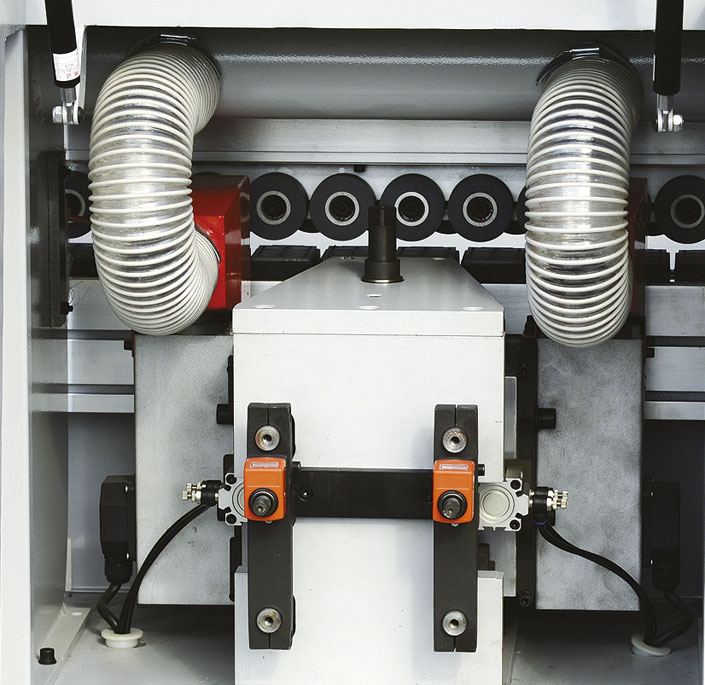

5. Rough trimming group: It can trim the exceeding edge on the panel roughly. It has double individual high- frequency motors.

6. Fine trimming group: It has two individual high- frequency motors and automatic tracking devices. It can make R2 on surface of edge band.

7. Corner trimming group: It makes corner of panels smooth and beautiful.

8. Scraping Group: It makes the surface perfect finishing after the borads be scraped

9. Hogging: Make a straight groove on the bottom or top of boards .

10. Buffing group: The edge of board is very smooth after the boards are polished. It has two polishing wheels and two motors.

Material Photo

Finish Prouct Photo

Factory Photo

Product detail pictures:

Related Product Guide:

we could supply good quality goods, aggressive cost and very best purchaser assistance. Our destination is "You come here with difficulty and we supply you with a smile to take away" for Fixed Competitive Price Industrial Edge Banding Machine - Automatic edge banding machine with pre-milling and hogging HZ450DJK – Golden, The product will supply to all over the world, such as: Niger, Mali, Egypt, With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we are striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

-

High Definition Plywood Edgeband - Automatic e...

-

Rapid Delivery For Small Edgebander Machine - ...

-

Wholesale Price Auto Panel Saw - Dust Free Tab...

-

Europe Style For Cabinet Edgebanding - Chinese...

-

Popular Design For Softforming Edgebander - Ch...

-

Massive Selection For Small Shop Edge Banding M...