Raw materials

A. Decorative paper PVC film, PU paper

B. Plywood, particle board, cardboard, MDF, gypsum board

C. PVAC glue, latex glue, UF glue

Feature:

This machine integrates automatic gluing, paper feeding, cleaning, gluing, pasting, hot pressing and film pasting.

Gluing and pressing adopt two types (optional): automatic lifting of full automatic shifter and semi-automatic cylinder (optional), with high accuracy. Input the desired plate thickness for automatic lifting.

The plate conveying is divided into idler conveying and conveyor belt conveying (optional). Even thin and light plates will not slip due to low friction.

The hot press roll and cold press roll are driven by the worm gear. The advantage of the worm gear is that there is no gap when driving, which can ensure the speed synchronization and stability.

The gluing roller is driven by two motors separately and the speed difference system is automatically compensated. There will be no glue mark on the material and the gluing quality will exceed the standards of the same industry.

The gluing roller is made of silica gel, which has the advantages of non sticking, easy cleaning and corrosion resistance.

There is a special automatic gluing system, which is convenient and fast to add glue without wasting glue.

It is equipped with a round shaft and a screw rod shaft. The screw rod shaft is mainly used to make PVC stretch to both sides for minor adjustment when pasting PVC

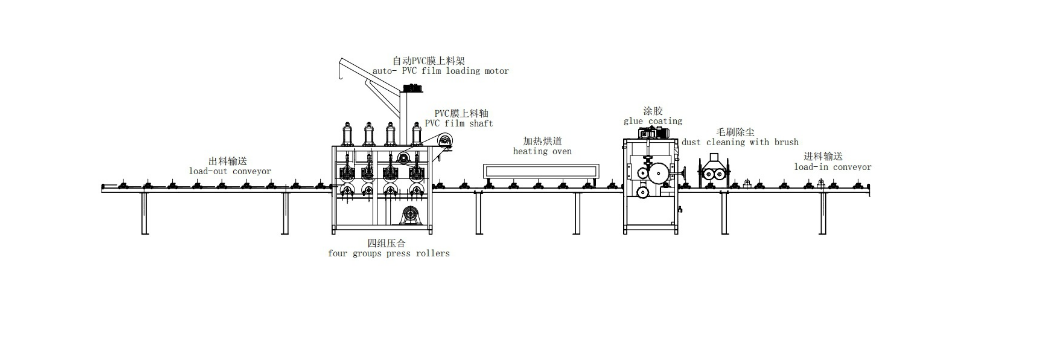

Equipment list:

1.Conveyor table(option: automatic loading)

2.dust cleaner

3.Glue coater

4.Heating channel

5.Sticking machine

6.Automatic cutting machine

7.Pressing machine

8.Conveyor table(option: automatic unloading)

| Model | COD-1300 |

| Panel size | 1220X2440/2750/3600 |

| Work thickness | 2-40mm |

| Work speed | 5-17m/min |

| Feeding power | 5.52kw |

| Heating power | 4.5 kw |

| Overall size | (L)13 X (W)3 X(H)3.5m |

| Adhesive | Cold glue |