Manufacturing Companies For Edge Band Cutting Machine - Bevel and straight edge bander HZ560DJK – Golden Detail:

Technical Data

|

Model |

HZ560DJK |

|

Pre-milling power |

1.8kw*2 |

|

Pre-milling motor for L shape |

4kw |

|

Ending trimming power |

0.37kw*2 |

|

Rough trimming power |

0.75kw*2 |

|

Fine trimming power |

0.75kw*2 |

|

Corner rounding power |

0.37kw*2 |

|

Feeding power |

3.7kw |

|

Edge band thickness |

0.4-3mm |

|

Edge band Max. width |

60mm |

|

Min length of workpiece |

80mm |

|

Feeding speed |

12-20m/min |

|

Air pressure |

0.7Mpa |

|

Total power |

19.78kw |

|

Overall dimension |

9400*900*1600mm |

|

Weight |

3000kg |

Function

1. Touch screen: Delta Touch screen makes your job easier.

2. Glue tank group: It has two glue tanks. One is for coating straight surface of boards and the other is for coating bevel of boards. It is designed a special structure to coat adhesive on edge band and boards uniformly. They can bond together firmly.

3. Pre-milling group: It has double milling units. One is for milling straight surface of boards and the other It is for milling bevel of boards.

4. Heater: It is for heating edge band.

5. End trimming group: It works by a precise guide track movement. The structure of automatic tracking and high -frequency motors ensure the surface of edge band smooth after cutting.

6. Rough trimming group: It has two individual high- frequency motors and can trim the exceeding edge on the board roughly.

7. Fine trimming group: It has two individual high- frequency motors and can trim the exceeding edge on the boards . It makes R2 on surface of edge band.

8. Corner trimming group: It makes corner of board smooth and beautiful.

9. Scraping Group: It makes the surface perfect finishing after the borads be scraped

10. Flat scraping group: It can clean extra adhesive on the board

11. Double Buffing groups: It has four polishing wheels and four motors. The edge of board is very mooth after the boards are polished.

12. Hogging: Make a straight groove on the bottom or top of boards .

Material Photo

Finish Prouct Photo

Factory Photo

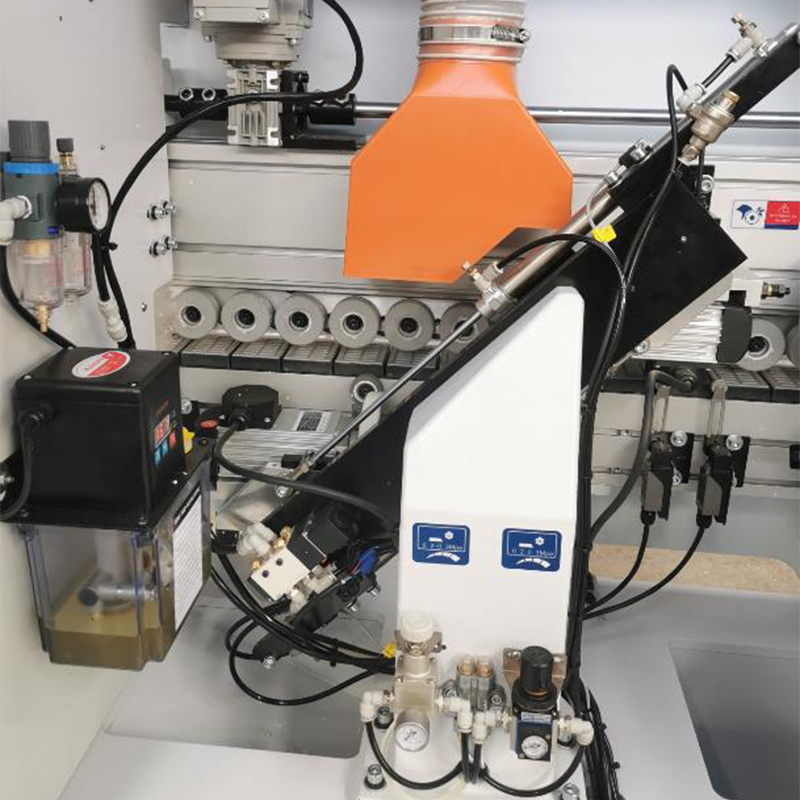

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Manufacturing Companies For Edge Band Cutting Machine - Bevel and straight edge bander HZ560DJK – Golden, The product will supply to all over the world, such as: Swiss, San Diego, Denmark, More than 26 years, Professional companies from all over the world take us as their long-term and stable partners. We are keeping durable business relationship with more than 200 wholesalers in Japan, Korea, USA, UK, Germany, Canada, France, Italian, Poland, South Africa, Ghana, Nigeria etc.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

-

Factory Directly Supply Circular Saw Table - S...

-

China OEM Contour Edgebander - Automatic edge ...

-

Reasonable Price For Panel Saw Machine - Wood ...

-

Chinese Professional Sliding Panel Saw Machine ...

-

High Reputation Pvc Edgebander - Automatic edg...

-

Best Price On Edge Banding Machine For Small Sh...