Manufacturing Companies For Edge Band Cutting Machine - Bevel and straight edge bander HZ560DJK – Golden Detail:

Technical Data

|

Model |

HZ560DJK |

|

Pre-milling power |

1.8kw*2 |

|

Pre-milling motor for L shape |

4kw |

|

Ending trimming power |

0.37kw*2 |

|

Rough trimming power |

0.75kw*2 |

|

Fine trimming power |

0.75kw*2 |

|

Corner rounding power |

0.37kw*2 |

|

Feeding power |

3.7kw |

|

Edge band thickness |

0.4-3mm |

|

Edge band Max. width |

60mm |

|

Min length of workpiece |

80mm |

|

Feeding speed |

12-20m/min |

|

Air pressure |

0.7Mpa |

|

Total power |

19.78kw |

|

Overall dimension |

9400*900*1600mm |

|

Weight |

3000kg |

Function

1. Touch screen: Delta Touch screen makes your job easier.

2. Glue tank group: It has two glue tanks. One is for coating straight surface of boards and the other is for coating bevel of boards. It is designed a special structure to coat adhesive on edge band and boards uniformly. They can bond together firmly.

3. Pre-milling group: It has double milling units. One is for milling straight surface of boards and the other It is for milling bevel of boards.

4. Heater: It is for heating edge band.

5. End trimming group: It works by a precise guide track movement. The structure of automatic tracking and high -frequency motors ensure the surface of edge band smooth after cutting.

6. Rough trimming group: It has two individual high- frequency motors and can trim the exceeding edge on the board roughly.

7. Fine trimming group: It has two individual high- frequency motors and can trim the exceeding edge on the boards . It makes R2 on surface of edge band.

8. Corner trimming group: It makes corner of board smooth and beautiful.

9. Scraping Group: It makes the surface perfect finishing after the borads be scraped

10. Flat scraping group: It can clean extra adhesive on the board

11. Double Buffing groups: It has four polishing wheels and four motors. The edge of board is very mooth after the boards are polished.

12. Hogging: Make a straight groove on the bottom or top of boards .

Material Photo

Finish Prouct Photo

Factory Photo

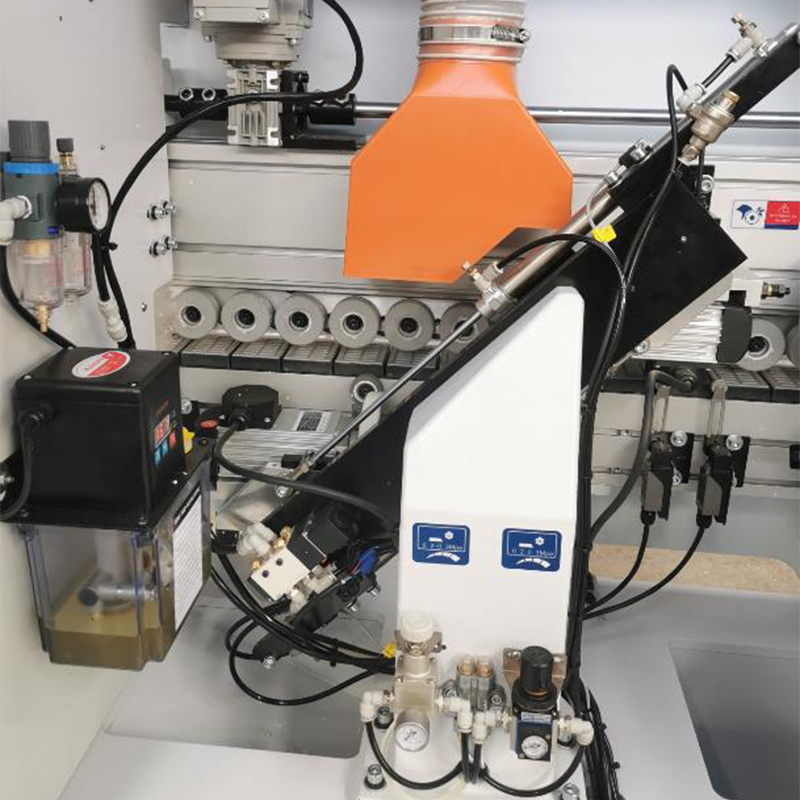

Product detail pictures:

Related Product Guide:

Sticking to the perception of "Creating products of top of the range and earning mates with people today from all over the world", we constantly put the desire of consumers in the first place for Manufacturing Companies For Edge Band Cutting Machine - Bevel and straight edge bander HZ560DJK – Golden, The product will supply to all over the world, such as: Miami, Singapore, Juventus, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.

-

Fast Delivery Curve And Straight Edge Bander -...

-

Top Suppliers Portable Table Saw - Semi-automa...

-

Professional China Auto Edge Banding Machine -...

-

China Cheap Price Sliding Panel Saw - Panel Sa...

-

OEM Manufacturer Portable Panel Saw - Panel Sa...

-

100% Original Factory Panel Saw Cutting Machine...