Detail

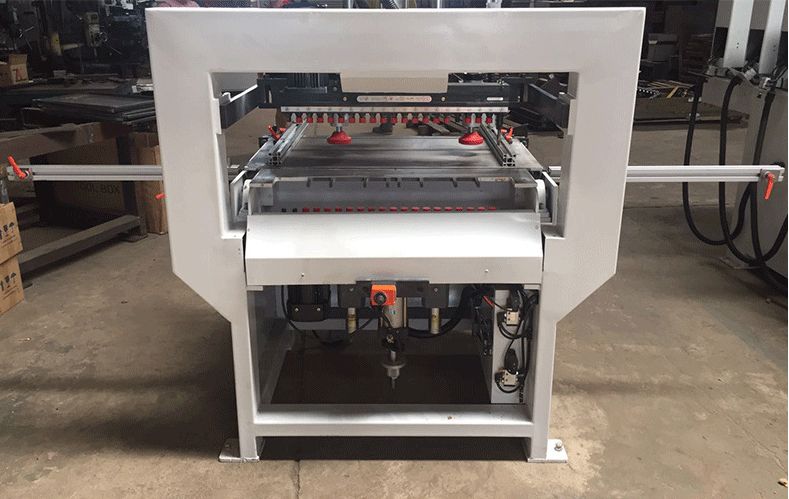

Multi- drilling machine is a multi -hole processing machine with multiple drill bits and all bits can work together. The multi- boring machine has many models such as single-row drilling machine, three- row drilling machine and six- row drilling machine. This type of drilling machine converts the traditional manual row drill action into mechanical action, which is automatically completed by machinery.

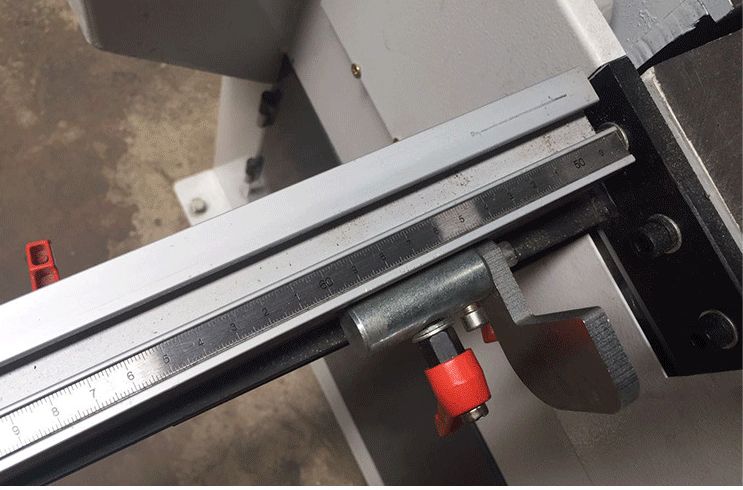

We should pay attention maintaining when the machine is running. Clean the machine table in time after the work is completed and clean the wood chips on the guide rail and the side to prevent jamming of the machine during operation due to debris interference. You should clean the lead screw regularly to prevent foreign matters from sticking to the lead screw. The lead screw is the most important part of the equipment, which affects the accuracy of the machine and plays an important role in the transmission process. Clean the industrial control box regularly. Dust is the biggest killer of drilling row. Dust removal and oil injection shall be carried out on the sliding track of drilling machine every week

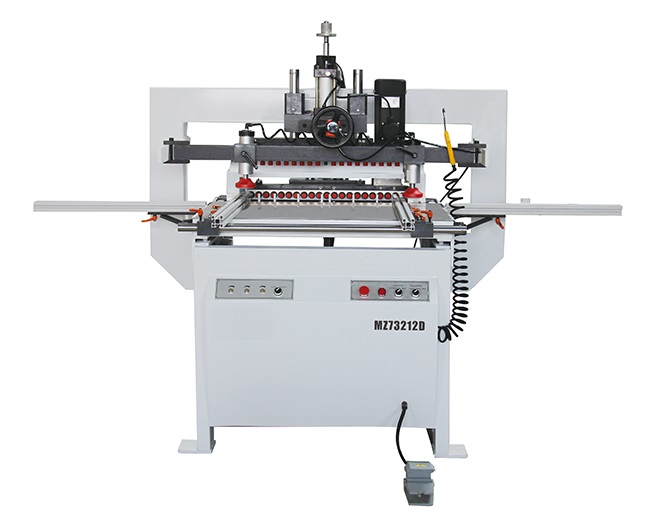

● The second row drill is equipped with a powerful pressing plate mechanism and a high-performance row head drill shaft, so that the second row drill can better reflect its working ability.

● The double -row drilling machine adopts the famous brand touch screen and PLC industrial control system, which has strong functions, low failure rate and wide drilling range.

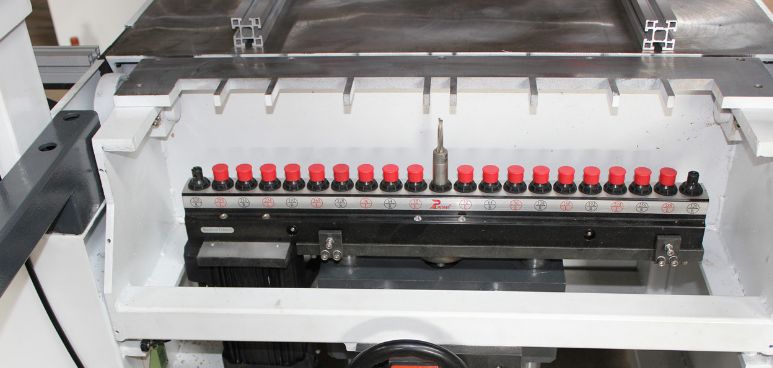

● All the bits of the double- row drilling machine adopt quick connectors, which is convenient and fast;

● The imported famous brand linear track makes the whole two-row drill durable. It uses high-quality steel and never deforms after heat treatment.

● This multi-boring machine is more effective.

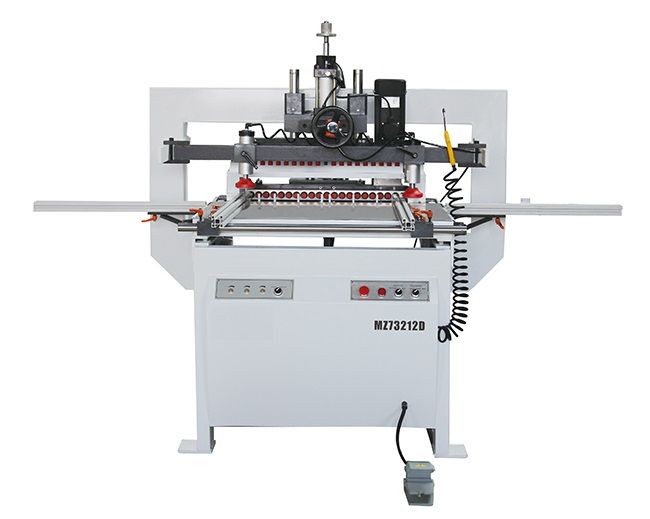

| Model | MJ73212D |

| Max hole diameter | 35mm(single bit) |

| Max drilling depth | 60mm |

| Spindle speed | 2800rpm |

| Total number of shaft | 21*2 |

| Air pressure | 0.6-0.8Mpa |

| Total power motor | 3kw |

| Overall size | 2000*1200*1500mm |

| Weight | 300kg |